| Page 1 | Page 2 | Page 3 | Page 4 | Page 5 | Page 6 | HOME |

Aquaculture is the term used to describe the managed cultivation of aquatic species, i.e. shrimp, catfish, trout, eel, shellfish, etc., commonly in an artificial system of ponds, raceways, and reservoirs. A properly managed aquaculture system includes high density stocking, intensive feeding, and careful management of water conditions, such as oxygen and ammonia levels, pH balance, etc.

The fish farmers who maintain high quality feed and clean water for their fish crops are rewarded with larger harvests of fish, commanding the highest market prices, while fish raised on poor feeds in polluted waters experience high mortality rates and develop an off-flavor that is penalized with a reduced market price.

Water pollution is a common problem experienced in all systems. In Norway, underwater mountain ranges, built up from fecal matter and uneaten feed in fjords and other traditional fish farm reserves, are forcing salmon producers to seek new territory. In the U. S., "small" trout farms produce sewage effluent equal to the sewage produced by a town with a population of 10,000 persons.

Although bacterial inoculants have long been used in the high dollar tropical aquarium fish industry, the low concentration of the existing formulas would require the application of more product than would be cost effective for large scale aquaculture farms. In the 1980s Alken-Murray Corporation changed the economic feasability of bacterial treatment by offering highly concentrated, non-pathogenic, and cost-effective Alken Clear-Flo® formulas to degrade excess nutrients, chemical pollutants, and ammonia.

The frequency with which water changes should be made depends on the normal water chemistry requirements of the species being raised and the degree to which the ideal water quality parameter can be maintained without additional water. Acidity and alkalinity (pH) evaporation, salinity, and other factors should be considered. A pond, or aquarium, which would normally require a complete water change may only need a partial water change after a treatment program with Alken Clear-Flo® is implemented.

Traditionally, in high volume shrimp producing nations, the pond waters are changed quite frequently. During this process, many shrimp burrowed deeply into the sandy bottom of the pond. While burrowing into the sand normally provides protection from other shrimp that might feed on their soft skinned bodies when they molt, the sandy bottom is also home to toxic sulfur reducing bacteria, including Desulfovibrio desulfuricans. Contact with these bacterial toxins may kill or at least greatly reduce the value of the shrimp.

A common practice employed during water changes includes removing the shrimp with nets, temporarily exposing them to the air. The air exposure causes drying of their bodies, weight loss and permanent stunting of their growth cycle. Mortality rates can exceed 15% each time these procedures take place. It is not unusual in some areas of the world for this procedure to cause losses to exceed 60% of the annual harvest.

Alken Clear-Flo® formulations offer up to 97% reactivation rates, for both dormant spores and vegetative strains, with rapid reproduction levels reached within 5 hours after reactivation. The selected, pre-adapted microorganisms in Alken Clear-Flo® are more aggressive than most pathogenic strains of bacteria, already in the water.

Alken Clear-Flo® 1000 and 1002 include basic spore forming, waste degrading strains of Bacillus to reduce organic loadings in the water column, preventing a buildup of sludge on the pond bottom. When Alken Clear-Flo® formulas are used, the nutrients dropping to the pond bottom are so reduced that the anaerobic sludge dwelling Desulfovibrio desulfuricans bacteria is unable to form toxic hydrogen sulfide gas. See our Hydrogen Sulfide tutorial for detailed information. These Alken Clear-Flo® formulas can also reduce sludge accumulations by up to 60%. See our Bio-Dredging article

Alken Clear-Flo® 1005, 1006, 1007 and 1200 contain bacteria that are pre-conditioned to prefer toxic pollutants, such as phenol, detergents, grease, and pesticides, in addition to the same basic bacteria that are found in CF 1000 and 1002.

Formulas such as Alken Clear-Flo® 1100, 1200, and 1400 contain Nitrosomonas europaea, which degrades ammonia to nitrite and Nitrobacter winogradskyi which degrades nitrite to nitrate in the aerobic environment of the water column, and to nitrogen gas in the anaerobic environment of the bottom sludge or gravel.

Although crude enzyme formulas offer the advantage of instant activation, massive doses are required when compared with the self-replicating enzyme factories present in bacteria. Bacterial formulations, distributed by many competitors, utilize older technology, including "freeze-drying", which often leave the bacteria weakened after revival from the dormant state. Reproduction of bacteria produced with older processes often does not occur or is not prolific enough to allow for small dosages, rendering these competing products financially unrewarding. (For more details, ask for our article titled Competitor Comparisons.) |

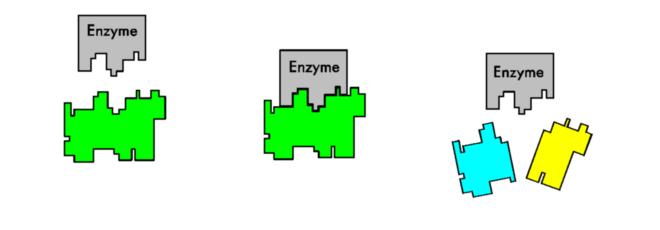

An Enzyme at Work Bacteria secrete distinctive enzymes that break down waste and toxins into simpler compounds that they can use as nutrient sources. The exact mechanism by which enzymes break down large molecules is uncertain, but it is believed to be related to a matching of molecular shapes. Additional information on basic enzymes produced by Alken-Murray bacteria is available if you follow the highlighted text. A relatively high dose initial treatment with an Alken Clear-Flo® series bacterial inoculant gives these beneficial micro-organisms a competitive advantage, while they establish a healthy biomass, that is then maintained with smaller supplemental doses, applied weekly or biweekly. When rains bring fresh water into open systems, feed, fecal matter and ammonia accumulate to the point of overload, requiring re-inoculation with the initial dosage to stabilize the system. After treatment with antibiotics or copper sulfate, the water should be changed, if possible, and Alken Clear-Flo® should be re-seeded to establish a healthy biomass.

Updated 07/01 |

| Page 1 | Page 2 | Page 3 | Page 4 | Page 5 | Page 6 | HOME |